Machinery and Equipment Manufacturing

India constitutes a pivotal sector driving industrial growth and infrastructure development. This sector encompasses a wide spectrum of production, including industrial machinery, agricultural equipment, construction machinery, and more, supporting various industries' needs that includes –

Raw Materials

Metals, plastics, electronics, and specialized materials required for manufacturing different types of machinery and equipment.

Design and Engineering Expertise

Skilled engineers and designers proficient in CAD (Computer-Aided Design) and other software to design and engineer machinery components.

Manufacturing Facilities

Specialized workshops, factories, or plants equipped with machinery for cutting, shaping, welding, and assembling components.

Machinery Tools

Cutting tools, lathes, milling machines, drills, and other specialized tools for shaping and fabricating metal and other materials.

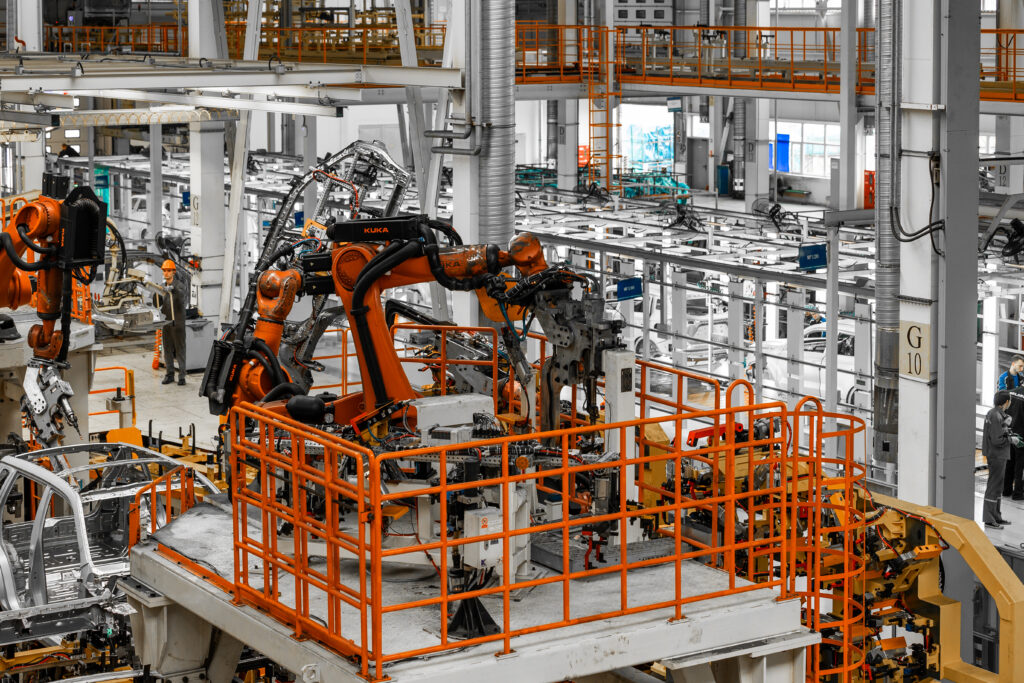

Automation and Robotics

Use of automated systems and robotics for precision manufacturing, assembly, and quality control.

Quality Control Systems

Inspection tools, testing equipment, and quality control measures to ensure the precision, durability, and functionality of machinery and equipment.

Supply Chain Management

Efficient sourcing of raw materials, components, and parts from suppliers and managing the supply chain for timely production.

Skilled Workforce

Trained technicians, machine operators, assemblers, and quality control personnel to ensure smooth operations and quality production

Safety Protocols

Adherence to safety standards and protocols to ensure a safe working environment for employees operating heavy machinery.

Research and Development

Investment in R&D to innovate, improve existing machinery, and develop new technologies for enhanced efficiency and performance.

Compliance with Regulations

Adhering to industry regulations, certifications, and standards governing machinery manufacturing for safety and quality assurance.

- By plural